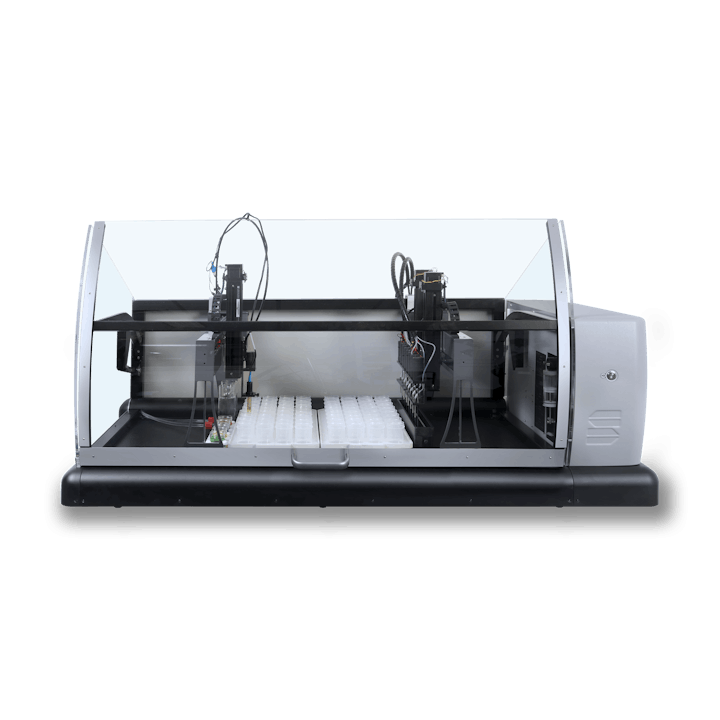

SP2000 Series

Turnkey or custom-made automation platforms

Skalar’s sophisticated SP2000 Series robotic analyzers offer dedicated and flexible automation solutions for routine analytical testing. Operating since 1965, we have finetuned our robotic laboratory equipment to meet the highest industry standards. Our automated testing robots are suitable for a large number of laboratory operations.

Routine analytical testing has never been this easy

The SP2000 Series automation solutions are available for a variety of applications, including:

- BOD

- COD

- test kit applications

- pH

- conductivity (EC)

- alkalinity and other titrations

- turbidity

- true color /apparent color / uv

- Ion Selective Electrodes (ISE) applications

- particle size distribution

- automatic weighing

- permanganate index

Combinations of analyses or applications are also possible. All applied methods comply with international regulations ISO, EPA, Standard Methods, DIN etc.

The modular design and flexible, user-defined automation allows the automated laboratory robotics to meet your exact requirements resulting in increased productivity and accuracy of results, while reducing the sample turn-around time, costs per sample and eliminating errors and operator/sample interaction. The complete platform is enclosed by protective front and side covers to comply with applicable CE regulations.

The robotic sample analyzers are controlled by our own RoboticAccess software package which includes pre-set application files, analyses scheduler, user-definable sample table set-up, user-definable print & export options to LIMS/Excel and an extensive set of QC features.

SP2000 Series robotic analyzers

The SP2000 Series platforms can be used for automatic sample preparation and/or automatic sample analysis.

Biochemical Oxygen Demand (BOD) analysis

BOD analysis is the most common application for water laboratories. The test is used as an indication of the organic pollution of water. Skalar's automation solution, the BOD analyzer, is one of the most flexible platforms available today. Besides the modern design and latest technological innovations, it can be configured from 18 up to 198 BOD bottles. The automated testing robots are developed to fit your exact laboratory requirements with respect to sample throughput, level of automation, sample capacity etc. Analyses are carried out with all major national and international regulations such as EPA 405.1/ISO 5815-1/ EN-1899-1/2, Standard Methods 5210 B and DIN 38409, as well as customer specific methods.

What can be automated?

- Sample pipetting

- pH measurement and/or setting of the sample

- Addition of nitrification inhibitor (ATU) and/or seed

- Addition of dilution water

- Sample mixing

- Measurement of initial dissolved oxygen value (DO1)

- Probe/stirrer rinsing between each measurement

- Bottle capping/de-capping

- Measurement of final dissolved oxygen value (DO2)

- Calculation of BOD according to required regulations

Want to see how it works? Click the button to watch our demo video.

Chemical Oxygen Demand (COD) analysis

COD analysis is commonly used to determine the number of organic pollutants found in surface water and wastewater. The COD value is a useful indicator for measuring the water quality. We offer various robotic automation solutions for the chemical analysis of COD values.

COD (ISO 15705/EPA 410.4/Standard Methods 5220 D)

The automation of this method is based on exactly the same reaction as the classical method, but instead of titration, a photometric detection is used. All the manual handling steps are automated. An advantage is the use of pre-prepared tubes, minimizing handling of toxic and hazardous reagents. The analyzers can be used with commercial available or self-made COD reaction tubes and is compatible with several photometers.

COD by titration (ISO 6060/Standard Methods 5220 B/DIN 38409 H41-H44)

The automated testing robots can be configured with 1-6 interchangeable sample racks, each with 20 positions. The samples can remain in the same vials from digestion to titration, thus preserving sample integrity. The SP2000 robotic analyzer is equipped with a titrator, burette tip, probe and stirrer. For range expansion without changing the burette, the platform can be configured with two titrators.

What can be automated?

- Sample mixing

- Sample titration

- Rinsing burette tip in between each measurement

- Calculation of COD value

SP2000 Testkit analysis

Many suppliers offer test kits for essential water and wastewater parameters such as COD, Total Phosphate, Total Nitrogen, Ammonium, and Nitrite. While these kits are simple and safe to use, they involve numerous manual steps like sample pipetting, unscrewing tube caps, and transferring tubes. This process becomes especially tedious and time-consuming as the number of samples increases or multiple parameters need to be analyzed. Unlike manual handling, which is time-critical and prone to error, the robot tracks and calculates precisely what needs to be done for each sample. The SP2000 robot, designed to accommodate 24 to 336 tubes per batch, streamlines this process by handling multiple applications simultaneously or sequentially at an individual sample level, greatly improving efficiency.

What can be automated?

- Sample pipetting

- Sample tube (de) capping

- Sample mixing

- Sample heating/cooling

- Addition of reagents

- Photometric detection

Conductivity (EC) can be measured as part of the automated sample preparation process prior to SP2000 Testkit analysis. Based on the EC value, the software can automatically select the optimal measurement range for robotic COD analysis. If necessary, the sample can also be diluted before analysis. Pre-qualifying samples in this way helps reduce costs by preventing the use of incorrect measurement ranges, thereby conserving test kit reagents and consumables. The robotic precision analyzer is compatible with test kits and photometers from various suppliers.

Want to see how it works? Click the button to watch our demo video.

EC / pH / titrations / turbidity / color / ISE analysis

Accurately controlling the quality of drinking water is very important. The SP2000 Series robotic analyzer offers water laboratories a complete “walk-away” concept. The typical parameters for water quality control such as dissolved oxygen, alkalinity, pH, conductivity, color (True, Apparent and UV) including filtration, turbidity can be fully automated thanks to this automation solution. Original sample collection bottles can be placed directly on the robot tester, avoiding any need for manual sample transfer. An integrated barcode scanner reads the barcode on the sample collection bottle. The sample ID, including the parameters to be analyzed, become visible in the sample table. The SP2000 Series laboratory robotics automatically starts the chemical analysis on this sample according to the data shown in the sample table. The results are directly visible after analysis. Depending on the application, calibration of the instrumentation can be performed automatically to ensure an accurate performance. Quality control checks and standards can be placed in between samples and probes can be re-calibrated automatically.

What can be automated?

- Barcode scanning for sample ID check and to gain the analysis parameters

- Bottle capping and de-capping

- In-line sample filtration or external via paperband filter

- Sample stirring

- Titration

- Rinsing of probe, stirrer, draining needle, filters and flow through cells

- Measurement

- Calibration of the instrumentation

- Result calculation

A dual titrator can be included for a higher sample throughput and a paper band filter can be integrated, allowing analysis of particle-laden water samples. The robotic sample analyzer is compatible with numerous current models of meters & probes from a variety of manufacturers. This configuration is expandable with fluoride, hardness and many other parameters.

Want to see how it works? Click the button to watch our demo video.

Soil-pH (ISO 10390)

The pH value of soil gives us information about how to improve the quality of soil, which results in increased crop quantities and cost reduction. The SP2000 Series robotic precision analyzer easily processes large quantities of soil samples every day. The system adds the required extractant to the sample, stirs, waits for a predefined time and determines the pH automatically. Any variables within these stages, such as the pre-stirring time and the stabilization criteria can be adapted at any time to accommodate all sample types and norms in one run.

What can be automated?

- Addition of extractant

- Sample mixing

- pH measurement

- Probe calibration and rinsing

The analyzer has a capacity of up to 576 containers (50 ml). For extremely large batches the precision analyzer can be configured with multiple electrode configurations, up to a total of 6 electrodes, for increased throughput. Besides pH analysis in soil, the analyzer can also be extended with the simultaneous Electrical Conductivity (EC) measurement.

Want to see how it works? Click the button to watch our demo video.

Particle size distribution analysis

Classification of soil is important for environmental control and construction purposes. Soil classification is based on several factors such as absorption, the ability to shrink or swell, water retention and permeability. Most of these factors independently correlate with the particle size of the soil. The clay fraction, the smallest fraction (0-2 micron), is indispensable in assessing soil quality. The clay fraction is measured according to for instance DIN/EN/ISO 11277 and 17892-4, CMA/2/11/A.6 and allows the soil to be categorized within stated classes. The analysis is carried out in three steps:

- Weighing the sample and separating the fractions

- Removal of organic matter and carbonates

- Determination of the clay fraction

Skalar has developed robotic laboratory equipment to automate the second and third step in this process. Automation of these steps is of particular interest because they can now be carried out fully automatic and with precise timing and pick up heights. The removal of organic matter and carbonates is automated on the SP50 Series robotic analyzer. With the SP2000 Series platform the determination of the clay fraction is automated.

What can be automated?

The SP50 sample preparation robot

The SP2000 clay fraction robot

- Addition of sodium pyrophosphate solution

- Addition of water

- Sample heating

- Addition of hydrogen peroxide

- Sample cooling

- Addition of hydrochloric acid

- Sample rinsing

- Addition of sodium pyrophosphate solution

- Addition of water

- Sample mixing

- Sample pick-up and transfer to the evaporation dishes

- Temperature correction for the sample pick-up depths

- Sample heating

The SP2000 Series can be configured with 14-105 positions for sedimentation cylinders (1000 ml) and 14-105 positions for evaporation dishes or vials. This procedure can also be performed unattended allowing for overnight operation. In addition, it is also possible to determine other fractions.

Sample preparation solutions

Automation of sample preparation not only speeds up laboratory procedures, but also saves valuable operational time and greatly increases accuracy, reproducibility and productivity. The SP2000 Series platform is ideal for automating sample preparation procedures in an efficient and precise way. Sample preparation techniques such as sample distribution, draining, dilution, filtration, addition of reagents, preservation, mixing, pH setting original sample, sample heating and cooling can be integrated. The automated laboratory robots are compatible with most sample containers, reagent containers, racks and can be equipped with multiple pipetting needles, stirrers and homogenizers. Various (de)-capping devices for vials, tubes and plastic bottles with screw caps, glass bottles with stoppers and containers with magnetic lids are available.

The SP2000 Series can perform the weighing steps necessary for “Loss on Ignition” (LOI). LOI is used to provide an indication of the organic content of a sample by monitoring the weight change after being heated to high temperature (offline up to 550°C in Skalar designed heat proof racks) where the sample loses some of its content by being burnt or volatilised. These racks are directly transferable to and from the oven and robot. Applications include the determination of organic matter content in materials such as sediment, sludge, soil and waste as well as industrial applications for the same parameter in cement, lime and bauxite.

The weighing robot is developed to assist in your Total Suspended Solid (TSS) analysis requirements. TSS analysis is a standard analysis in the wastewater industry as the results of the TSS analysis are used to assess the performance of conventional waste treatment processes and water quality. This application completely automates the time consuming weighing process, allowing your analysts to focus on other duties. Moreover, this automation means that conventional working hours of a laboratory can be greatly extended.

Software

RoboticAccess is designed as a flexible and multitasking program for controlling the Skalar robotic sample analyzers. While analyzing the samples, already obtained results are processed and new analyses can be prepared and scheduled. An access code and password are required before operation to prevent unauthorized operation and data modification. The application files, which contain the instructions for the robotic laboratory equipment to perform the specifications, are pre-set in the software by Skalar, according to (inter) national regulations or can be in accordance with user defined requirements. Runs can be easily started by selecting the required application and simply creating a user defined sample table by dragging the racks to the analyzer. When the sample table is completed and the analysis sequence is defined, the run can be started or scheduled for another start time.

All applications can be programmed to be analyzed. The status of the running analysis can be followed on the screen and the results are displayed in real-time. During the run it is possible to add priority samples or exclude samples from measurement. Results can be printed in user defined print reports and exported to a txt, Excel or LIMS. Finished runs can be archived as well as backed up and restored later. Integrated Quality Control features assure accurate results and full compliance with required regulations. QC samples can be analyzed and Quality Control charts together with other valuable statistical information can be created. CLP protocols can also be included, which allow automatic actions of the robot tester itself if QC and CLP limits are exceeded. This guarantees the production of highly accurate results and automatic quality control on the robotic analyzer’s performance.

Industries we serve

Sure there is more we can serve, but we did not yet list them all.

Reach out to us for tailored automation solutions

Are you in search of reliable robotic laboratory equipment for routine chemical analysis? Our laboratory automation solutions are suited for a wide range of applications and industries. Reach out to us to inquire about the possibilities and request a quote for your automated testing robots. Apart from robotic sample analyzers, we also offer wet chemistry analyzers and other automated analyzing tools.